Design

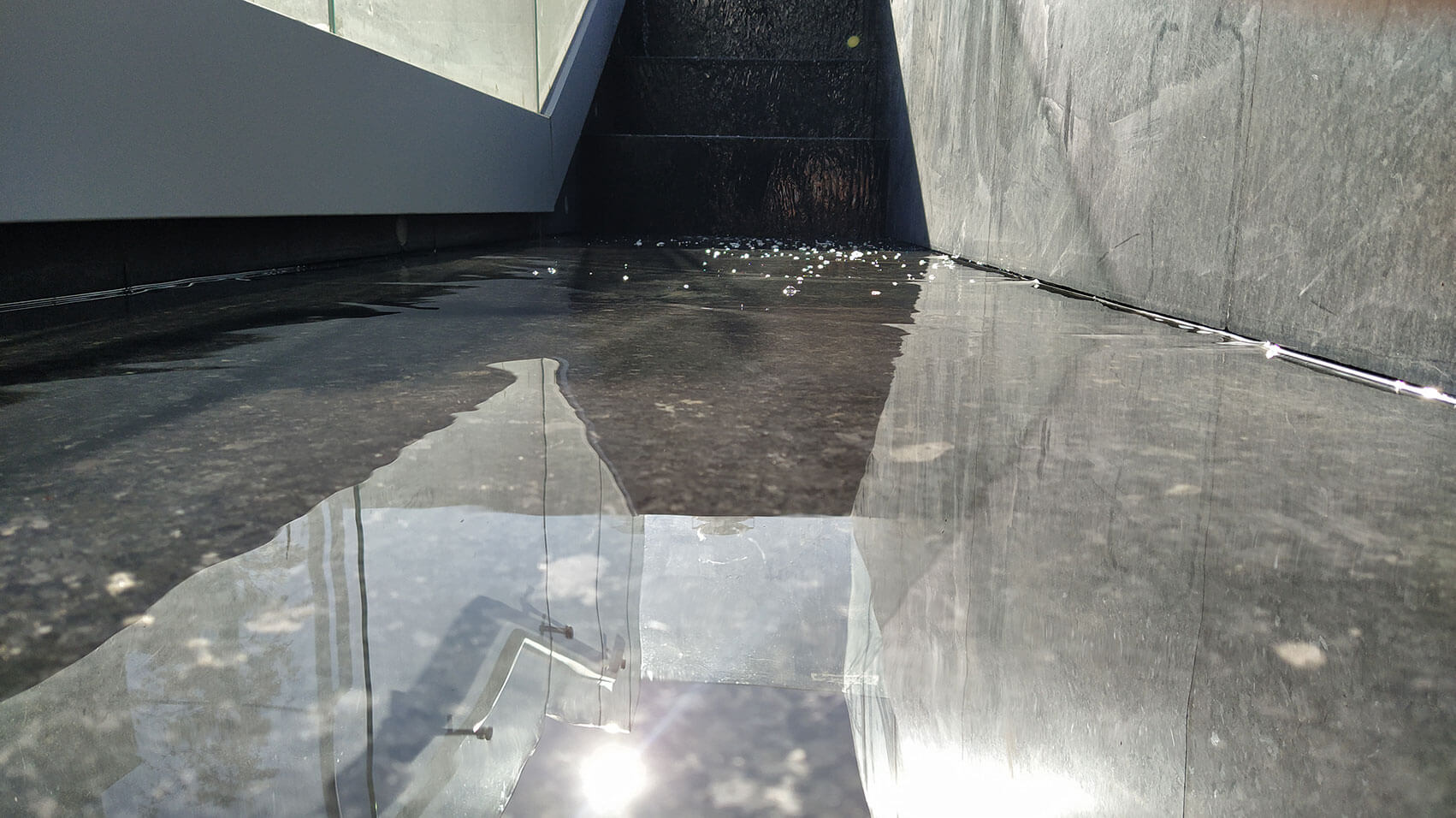

Once the project was defined, it was decided that the fountain itself would be walk-through attraction in a clear paved area in one of the park’s squares This decision was taken due to the fact that walk-through fountains are the most accessible when creating water displays as well as being quite versatile, as the area concerned can be used for other alternative uses when the fountain is not in operation.

The second point that had to be taken into account in relation to the fountain design was the shape and size of the park’s fountain. As can be seen from the plans, the fountain’s boundaries are adapted to the shape of the square, leaving free walking areas on both sides of the square, always prioritising pedestrians’ freedoms.

We aim to transmit and create sensations through the movement of the fountain’s water and light. According to the impressions that one wishes to create for the visitor, the type and number of jets are designed along with the distribution of space available.

Installation

The fountain was installed in a period of three months. We can divide the process into three phases, which on occasions overlapped:

Civil works

Which included excavation and ground levelling work where the systems were to be installed. During this phase we have to take into account the location of the technical room, where the majority of the systems are found and its conduits to the fountain base. This room should be accessible for subsequent maintenance of the fountain.

During this phase the 13 concrete utility boxes were built for subsequent placement of the 13 rows of jet installations. These utility boxes were made watertight for when the fountain is in operation.

Installation of hydraulic and electrical parts.

This was the most laborious phase due to the size of the project. This phase had to be coordinated with the civil works due to the fact that all parts were underground.

Once the utility boxes and technical room were prepared, installation of the pipes, pumps, nozzles and other necessary hydraulics took place.

The installation comes with water pumps, a centralised water treatment system, connected to each utility box, connection and drain.

Grids are installed covering the utility boxes, which collect the returned water and individual LED lighting for each of the 234 jets.

Connection and putting into operation:

Once all the parts have been correctly fitted, all the equipment’s electrical connections are connected to the control panel located in the technical room. This panel is equipped with our Syncroshow® software, developed and improved throughout the last 20 years, which allows control of the fountain at all times from any device with access to the Internet.

Thanks to the software, all the fountains’ elements are programmed in order for them to act according to the specific timetables, weather conditions etc. For example, the anemometer, which is an important part of this type of fountain, regulates the jet height in function of wind speed.

This software comes with a highly intuitive design, which allows simple modification of the parameters during maintenance.

After connecting all the parts and programming the specific operation parameters, the putting into operation tests took place.

Sustainability

This project is completed in accordance with European sustainability criterion. It is a reliable technical solution, highlighting the installation of hard wearing and high-quality materials, such as the use of stainless steel for hydraulic systems.

It has been designed in order to make the most efficient use of all resources required for its operation. Installation of low power LED lights is one way this has been achieved.

The water treatment allows us to reuse the water, significantly reducing consumption, which reduces the required amounts due to water loss because of evaporation, and partial replacements for installation maintenance, always focusing on safety and water quality.

The fountain comes with different modes allowing us to program it according to the timetable, in order to offer various effects.

- Static: continuous operating mode, which comes with small variations.

- Water displays: variations in height and jet operation during the day via various program sequences.

- Water and light displays: in which changes of light colour interact with the water displays at night.

- Eco: Basic operation mode for low-level public periods.